-

-

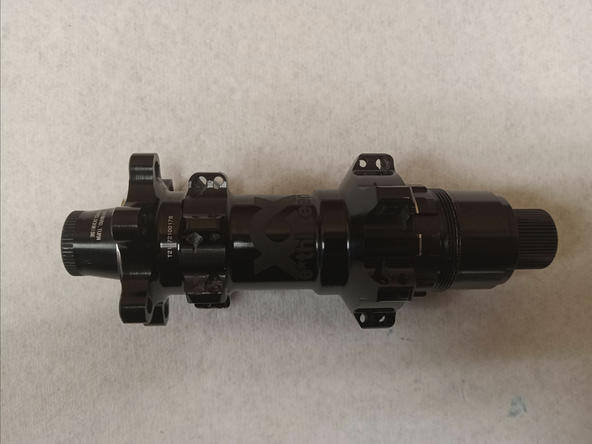

Start with a clean work surface, have a clean rag and light freehub grease ready.

-

The grease we use in our hubs is Mobil XHP 222.

-

XCX Gravel Hubs are only compatible with our XCX Gravel Hub Service Parts and XCX Gravel Freehub Bodies.

-

-

-

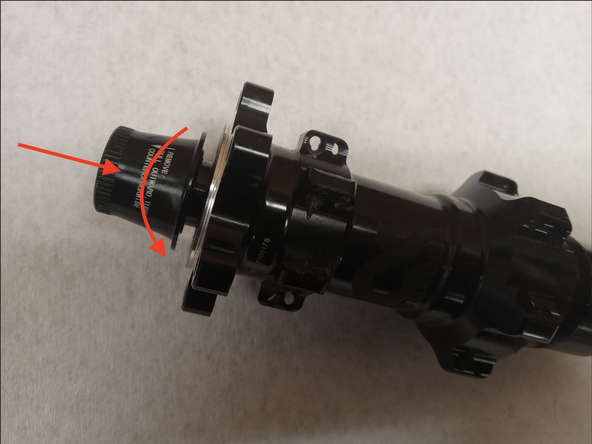

To remove axle pull non-drive endcap away from the hub while turning counter-clockwise.

-

-

-

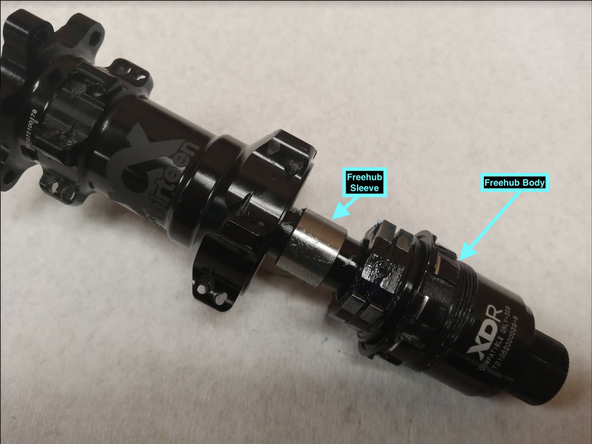

Once the non-drive endcap is removed you can pull the freehub and axle out of the hub shell.

-

Be careful not to loose/misplace the freehub sleeve! These sleeves help to properly space the freehub body and the hub can not be used without this. If installing a different model of XCX Gravel Freehub be sure to use the sleeve which is included. This will help to ensure proper spacing/assembly.

-

-

-

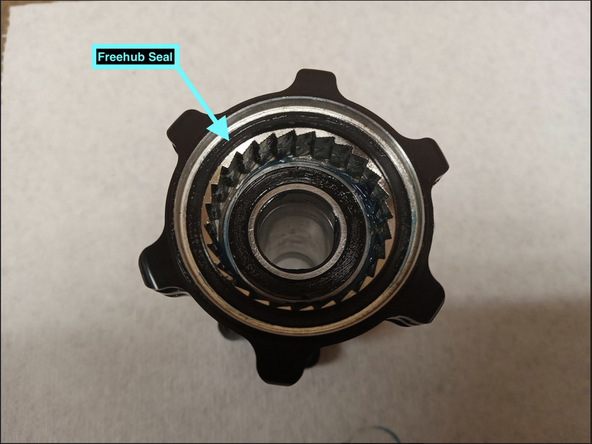

In many cases removing the freehub seal is not necessary and the seal can be simply cleaned by wiping off old grease/debris with a clean rag.

-

If your freehub seal is excessivly dirty/damaged it may be a good idea to remove and service or replace it. New freehub seals are included with all of our freehub body kits.

-

To remove the seal, gently pry the seal out from the hub using a sharp pick or flatblade screwdriver. Be careful not damage/bend the seal when removing.

-

-

-

Clean the hubshell and seal thoroughly using a clean shop rag or microfiber cloth. A mild degreaser can be used if needed.

-

Lightly grease the drivering and freehub seal.

-

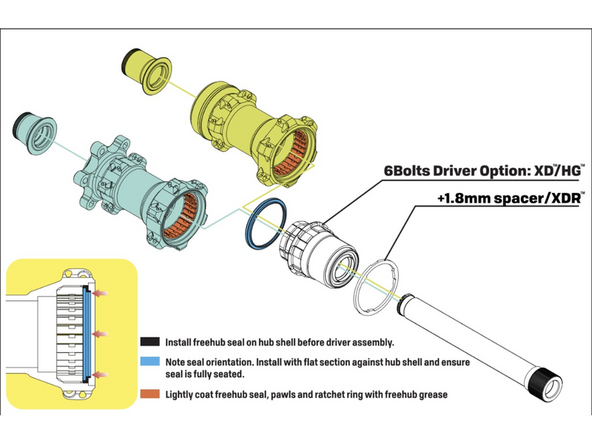

Gently press the seal back into place, ensuring it is evenly pressed/seated in the hubshell. Please note the freehub seal is directional. The diagram in the second image shows this for reference.

-

-

-

Clean all parts thoroughly using a clean shop rag or microfiber cloth. A mild degreaser can be used if needed.

-

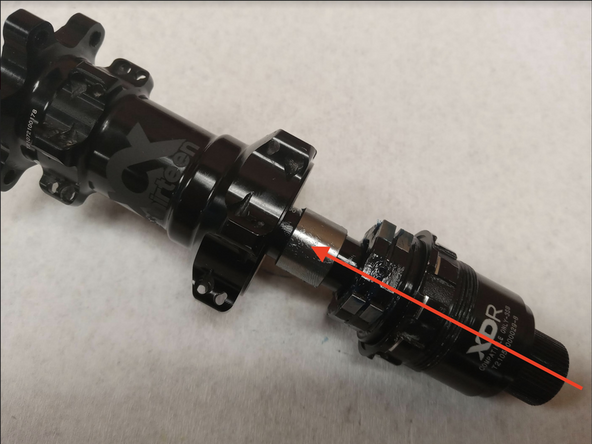

Slide the freehub and freehub sleeve onto the axle, and install in the hubshell.

-

Slightly rotating the freehub body counter clockwise while reinstalling can help everything to align.

-

Freehub Sleeves are specific to freehub model. If installing a new freehub please ensure you are using the one which was included with your freehub.

-

New freehubs include a new freehub seal which can be used if needed. Its important to ensure only one seal is installed in your hubshell. Accidentally installing an additional seal can cause excess drag.

-

-

-

Install non-drive axle endcap. Apply pressure and tighten clockwise until endcap spins freely.

-

Wipe off any excess grease and you are good to go!

-

Thanks for reading, now get out there and ride!

Thanks for reading, now get out there and ride!