Introduction

This guide will instruct on the installation process for e*thirteen Helix direct mount chainrings onto Helix Cranks

Tools

Parts

-

-

Lay out parts on a clean workbench workbench.

-

If installing ring on a used crank, ensure direct mount interface splines are clean.

-

-

-

Identify the chainline requirements of your bike. Helix rings are flip-flop and can achieve either 53mm (Boost) or 56mm (Super Boost) by turning the ring over.

-

Ensure splines are clean and add a very light layer of grease to the spline interface on the chainring.

-

Slide the ring onto the direct mount splines with the chainline size you need facing outward and the arrow showing "Pedal" aligned with the crank arm access.

-

Thread on the silver chainring lockring by hand until it bottoms out on the chainring.

-

-

-

The chainring lockring will need to be tightened to 30Nm of torque.

-

The preferred method to achieve correct torque spec is to use a torque wrench.

-

The e*thirteen chainring lockring tool which is provided with the cranks has 2 interfaces which can be used - 36mm flats for a crowsfoot attachment or Shimano FC-32 Tool Spline interface.

-

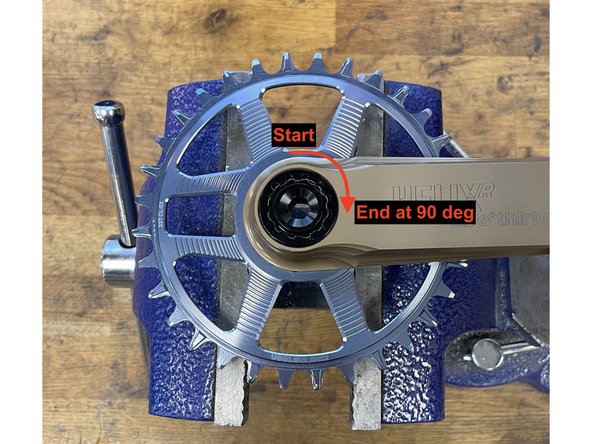

If a torque wrench is not available proper torque can also be achieved by turning the lockring 90 Degrees from it's hand tight snug position.

-

If using the snug +90 degree method, the easiest way to achieve this is to put the chainring lockring tool in a vice. Alternatively a large crescent wrench can also be used.

-

-

-

Ensure that the lockring is sitting below the cranks flange that interfaces with the BB.

-

Reinstall crankset on bike and time for a ride!

-

Thanks for reading, now get out there and ride!

Thanks for reading, now get out there and ride!