-

-

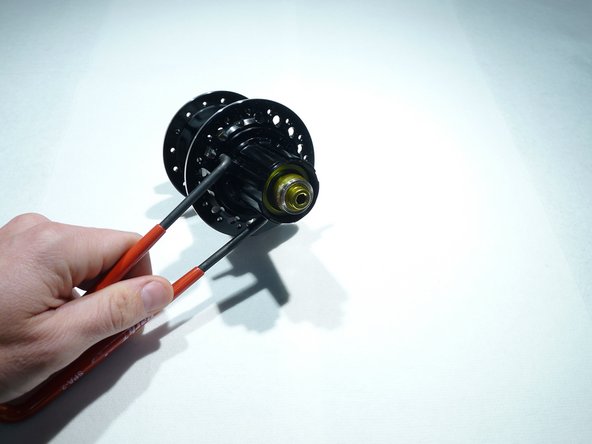

Remove freehub lockring by turning counter clockwise with pin spanner

-

-

-

Using two 5mm hex wrenches, loosen the endcaps by turning them counter clockwise from each other

-

The driveside endcap will normally loosen first

-

-

-

Remove the driveside endcap

-

Slide freehub assembly off of the axle

-

Be careful not to lose the pawls as they may fall while removing the freehub body

-

-

-

Use an axle vise or insert the flats on the drive side of the axle into a smooth jaw vise

-

While holding the axle in the vise, loosen the non-drive endcap by turning it counter-clockwise

-

-

-

The preload adjuster may need to be held with a cone wrench while loosening the non-drive endcapdrive side

-

Loosen the preload ring by turning it clockwise

-

Slide the axle out of the hub shell by pushing from the non-drive side to the drive side

-

-

-

Slide the hub body off of the axle

-

At this point the hub is most of the way apart, you can service bearings, replace worn parts or just clean things up

-

Next, Let's install the axle

-

-

-

Lightly grease steel axle

-

Remember the drive side of the axle is the side with the bearing surface for the freehub body

-

Slide the axle into the hub from the driveside

-

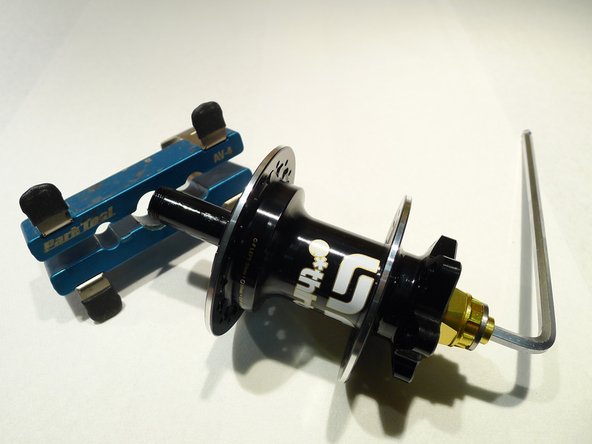

Use an axle vise or insert the flats on the drive side of the axle into a smooth jaw vise

-

-

-

While holding the axle in the vise, install the preload adjustment ring by turning it counter-clockwise

-

Tighten the preload adjuster by hand

-

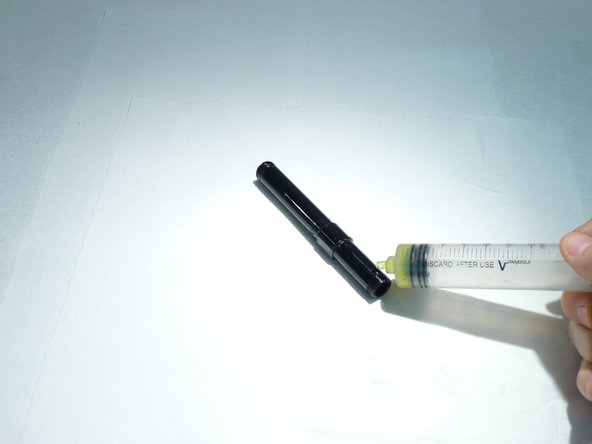

Put two drops on medium strength thread locker on the threads inside the non-drive side axle

-

-

-

Install the non-drive endcap by turning it clockwise

-

Lightly grease the face where the endcap and preload ring will meet

-

Adjust the bearing preload using the preload ring

-

Tighten the preload ring so the bearings no longer have play in them, but such that they also do not have excess drag

-

-

-

When you are happy with the adjustment, hold the preload ring with a cone wrench and tighten the non-drive endcap to 6nm

-

Remove the axle from the vise

-

-

-

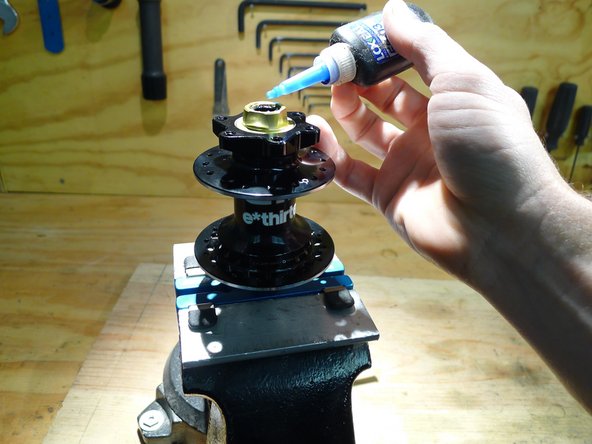

Next, install the freehub assembly

-

Learn how to lube the freehub properly using the freehub service instructions

-

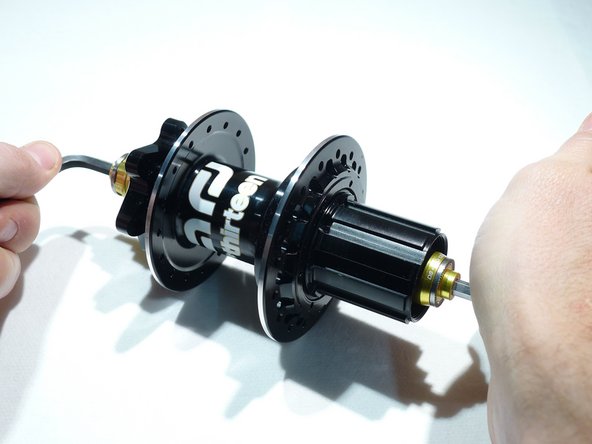

Slide the freehub body over the axle

-

Turn freehub counterclockwise so that the pawls compress the springs and slide into the hub

-

A tool may be used to lightly compress the pawls

-

-

-

Put one drop of medium strength threadlocker on threads inside the driveside endcap

-

Install the endcap by turning clockwise

-

Tighten to 6nm

-

-

-

Reinstall the freehub dust seal by turning clockwise

-

tighten to snug

-

Thanks for reading, now get out there and ride!

Thanks for reading, now get out there and ride!